Pressure Gauges

What Are The Types of Pressure Gauges?

07 Sep , 2020 News

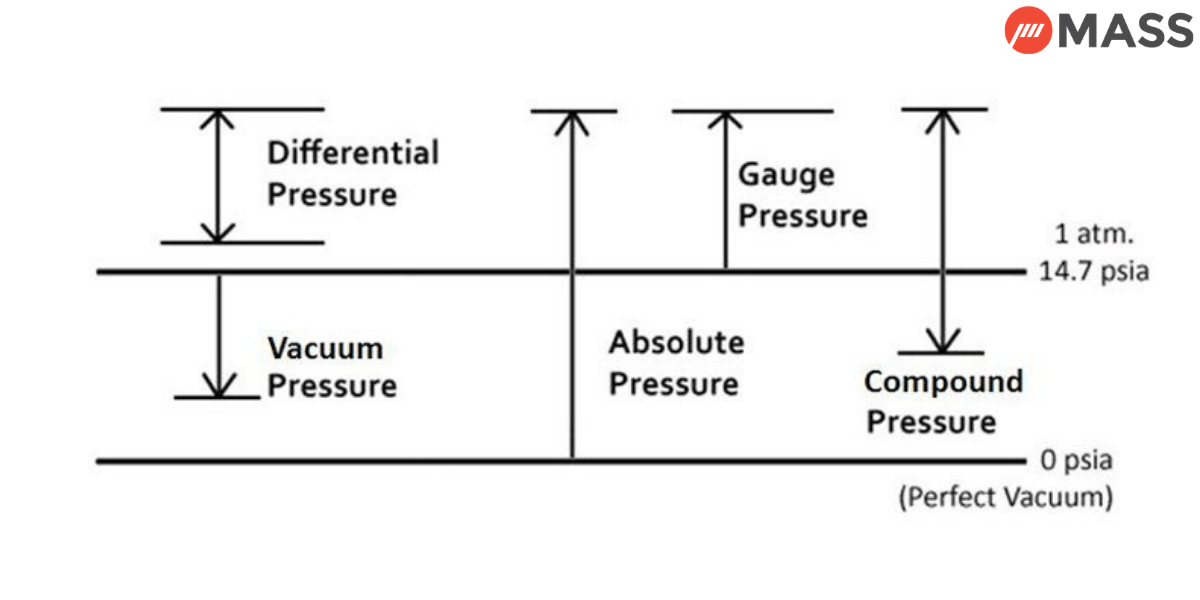

The devices that are used for measuring pressure are called pressure gauges. Simply put, pressure is the amount of perpendicular force applied to per unit area of a surface. Researchers have developed many techniques for measuring pressure. To measure pressure correctly, it is critical to consider what reference point is being used to measure it against. Accordingly, it is classified into ‘absolute’, ‘gauge’ or ‘differential’ pressure. A pressure gauge may be a hydrostatic one or a mechanical one.

Liquid column or piston type gauges measure pressure by comparing it against the per unit area of hydrostatic force at the bottom of a column of fluid. Other kinds of pressure gauges, like those that use diaphragms, Bourdon tubes or bellows, measure pressure by using mechanical motions.

Pressure gauges are well suited to measuring the three different types of pressure.

1. Absolute Pressure Gauges

A. Absolute Pressure Measurement – Absolute pressure is measured with reference to the pressure that exists in a full vacuum. The pressure at complete vacuum is zero. Therefore, it is called ‘absolute’ pressure.

B. Description of Measuring Instruments – A typical mechanical absolute pressure gauge consists of a measuring cell, separated by a diaphragm. One portion of the instrument is the reference chamber and is a vacuum. A barometer, which is a hydrostatic gauge can also be used to measure absolute pressure.

C. Applications – Absolute pressure gauges can be used to measure the vapor pressure of liquids, vacuum reactors, to check leakage in tanks and circuits and to measure the fall in pressure of distillation vacuum columns, to monitor adiabatic saturation pressure by meteorologists and to perform distillation operations in the oil refining industry. Absolute pressure gauges are also used in vacuum pumps and in the food packaging industry. Barometers are used to measure atmospheric pressure.

2. Gauge Pressure Measuring Devices

A. Gauge Pressure Measurement – Gauge pressure is measured with reference to the standard atmospheric pressure at sea level (approximately 1013.25 mbar). Gauge pressure is positive when it is more than atmospheric pressure, and negative when it is lesser than atmospheric pressure.

B. Description of Measuring Instruments – The most commonly used device to measure gauge pressure is a Bourdon tube pressure gauge. It is a mechanical device which consists of a tube formed into a C-shape and sealed at one end. The sealed end is free to move a pointer over a scale according to the applied pressure within the tube, entering through the open end. Other mechanical devices like diaphragms and bellows can also measure gauge pressure. Among hydrostatic ones, the u-tube manometer is effective.

C. Applications – Gauge pressure measuring devices are the most widely used pressure measuring instruments for industrial purposes, particularly in power, refineries, chemical, petrochemical, pharmaceutical, food, refrigeration, air-conditioning and sanitation industries.

3. Differential Pressure Gauges

A. Differential Pressure Measurement – Differential Pressure is only the measure of the difference between two pressure readings. It does not offer any information about the levels of pressure at the two individual points that it compares.

B. Description of Measuring Instruments – Differential pressure gauges are usually mechanical in nature. The major types of gauges for measuring differential pressure are Piston-style, Diaphragm type and Bellows differential pressure gauges. Each have specialized application in different industrial processes.

C. Applications – Differential pressure gauges find applications in various industries for monitoring filtration, liquid level, and liquid flow. These are useful in refineries as well as petrochemical and chemical plants, power plants and clean room.

Types of Pressure Gauges According to Usage

1. Commercial and Industrial Pressure Gauges – Commercial gauges are general purpose pressure measuring instruments commonly used in Heating Ventilation Air Conditioning (HVAC) and Refrigeration. Industrial pressure gauge is suitable for production processes that would not block the pressure system. Industrial gauges are used in manufacturing industries, OEM applications, hydraulic, water treatment and RO industries.

2. Process Pressure Gauges – In industries where the production process functions under extreme conditions, subjected to vibrations, pressure spikes and a corrosive environment (like in certain areas of petrochemical and other chemical industries), a process pressure gauge can be safely used.

3. Low Pressure Gauges – These are suitable for measurement of liquid and gaseous pressure, provided they don’t obstruct its functioning. Plants construction processes, pneumatic systems and cleanrooms often need low pressure gauges.

4. Seal Gauges – These gauges are designed to seal potential leak paths and are used in variety of industrial applications to meet material compatibility requirements, viscous applications, corrosive chemicals, vibrations, sanitary and pharmaceutical requirements.

5. High Precision Test Gauges – These gauges are well-suited for processes that require precise calibration as in testing laboratories.

6. Duplex Pressure Gauges – These are a type of differential pressure gauge that can function in extreme environments and measure the difference between two applied pressures. This is sometimes required in refrigeration, fuel, chemical and air-handling Industries.

Choosing the Right Pressure Gauge

Factors like the level of accuracy required, appropriate dial size for readability, durability of material to suite environment and process conditions , mounting options available and the range of pressure that it can measure and pressure type to be measured determine what kind of gauge may be right for you to use. If you choose a manufacturer who gives you a wide variety of gauges to choose from, choosing the right one will be an uncomplicated process.

Frequently Asked Questions Around Pressure Gauge

1. What is a Pressure Gauge?

A. A pressure gauge is a fluid intensity measurement device.

2. What are pressure gauges used for?

A. Pressure gauge, instrument for measuring the condition of a fluid (liquid or gas) that is specified by the force that the fluid would exert, when at rest, on a unit area, such as pounds per square inch or newtons per square centimetre.

3. What are two types of pressure?

A. There are two basic pressure types, absolute and gauge.